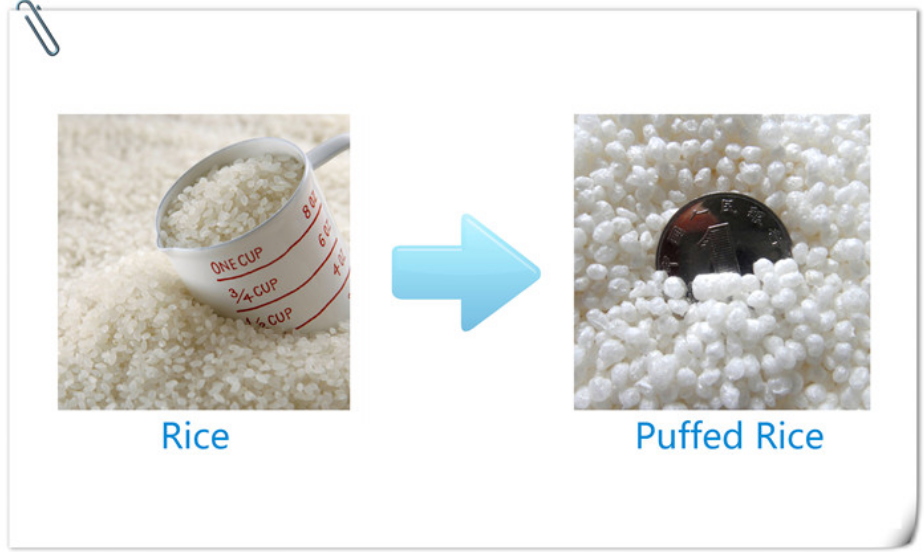

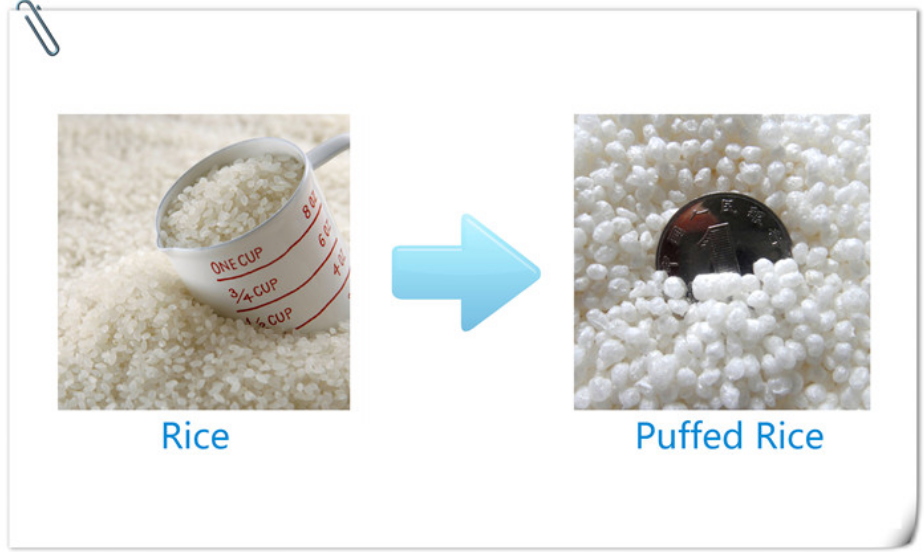

Puffed rice is a popular snack enjoyed around the world, known for its light texture and satisfying crunch. The production of puffed rice involves specialized machinery designed to transform raw grains into the airy, puffed variety. This article delves into the working principle of puffed rice forming machines, detailing the stages of production, the technology behind the process, and the benefits of using such equipment.

Introduction to Puffed Rice Forming Machines

Puffed rice forming machines are sophisticated pieces of equipment that utilize heat and pressure to convert rice grains into puffed rice. These machines are integral to modern puffed rice production, ensuring consistency, quality, and efficiency. The process involves several key components and stages, each critical to achieving the desired texture and flavor.

Components of Puffed Rice Forming Machines

1. Feeding System

The feeding system is the first stage in the puffed rice production line. This system ensures a steady and controlled flow of raw rice grains into the machine. It typically includes a hopper or conveyor that transports the grains from storage to the main processing unit. The precise control of the feeding system is crucial for maintaining consistent production rates and ensuring uniform puffing.

2. Pre-Conditioning Chamber

Before the rice grains can be puffed, they need to be pre-conditioned. This stage involves slightly heating and moistening the grains to prepare them for the high-temperature, high-pressure environment of the puffing chamber. The pre-conditioning chamber ensures that the grains are uniformly treated, which is essential for achieving even puffing.

3. Puffing Chamber

The puffing chamber is the heart of the puffed rice forming machine. In this chamber, the pre-conditioned rice grains are exposed to high temperatures and pressure. The combination of heat and pressure causes the moisture inside the grains to vaporize rapidly, leading to an explosive puffing effect. The precise control of temperature and pressure in this chamber is critical for producing high-quality puffed rice with the desired texture and appearance.

4. Cooling System

After the grains are puffed, they need to be quickly cooled to stabilize their structure and prevent further expansion or collapse. The cooling system, often consisting of fans or cooling conveyors, rapidly reduces the temperature of the puffed rice. This stage is essential for preserving the crispiness and shape of the final product.

5. Flavoring and Coating Unit

In many puffed rice production lines, a flavoring and coating unit is integrated to enhance the taste and appearance of the final product. This unit applies seasonings, sweeteners, or other coatings to the puffed rice, ensuring an even distribution of flavors. The flavoring process is often followed by a drying stage to set the coatings and ensure the product's shelf stability.

6. Packaging System

The final stage of the puffed rice production process is packaging. The packaging system ensures that the puffed rice is hygienically packed in suitable materials, protecting it from moisture and contamination. Modern packaging systems also incorporate features like vacuum sealing and modified atmosphere packaging to extend the shelf life of the product.

Working Principle of Puffed Rice Forming Machines

Heat and Pressure Application

The core working principle of puffed rice forming machines is the application of heat and pressure. When rice grains are subjected to high temperatures and pressure, the moisture inside them turns into steam. The sudden expansion of steam causes the grains to puff up. This principle is similar to the way popcorn pops, but the conditions and machinery used are specifically tailored for rice.

Controlled Environment

Maintaining a controlled environment within the puffing chamber is essential. The temperature and pressure must be carefully monitored and adjusted to ensure that the rice puffs uniformly. Too much heat or pressure can burn the grains, while too little will result in incomplete puffing. Advanced puffed rice forming machines are equipped with sensors and automated controls to maintain optimal conditions throughout the process.

Moisture Management

Effective moisture management is another critical aspect of the puffing process. Pre-conditioning the rice to achieve the right moisture content is essential for consistent puffing. The moisture must be uniformly distributed within each grain to ensure that the puffing occurs evenly. This is why the pre-conditioning chamber plays a vital role in the overall success of the puffing process.

Advantages of Using Puffed Rice Forming Machines

1. Consistency and Quality: Puffed rice machines ensure a high level of consistency and quality in the final product. The precise control over temperature, pressure, and moisture levels results in uniformly puffed rice with the desired texture and flavor.

2. Efficiency: These machines are designed for high-efficiency production, capable of processing large quantities of rice in a relatively short amount of time. This efficiency is essential for meeting the demands of commercial production and ensuring a steady supply of puffed rice.

3. Automation and Control: Modern puffed rice forming machines come with advanced automation and control features. These include programmable settings, real-time monitoring, and automatic adjustments, which reduce the need for manual intervention and minimize the risk of errors.

4. Versatility: Puffed rice forming machines are versatile and can be used to produce a variety of puffed grain products, not just rice. This versatility allows manufacturers to diversify their product offerings and cater to different market demands.

5. Cost-Effectiveness: While the initial investment in puffed rice forming machines can be significant, the long-term benefits in terms of efficiency, consistency, and reduced labor costs make them a cost-effective solution for puffed rice production.

Conclusion

The working principle of puffed rice forming machines is based on the controlled application of heat and pressure to achieve the puffing of rice grains. These machines offer numerous advantages, including consistency, efficiency, and versatility, making them essential equipment for modern puffed rice production.

If you are in need of a reliable supplier or have further questions about puffed rice forming machines, please contact us for more information. Our team is ready to assist you with all your needs and ensure you have the best equipment for your production line.