If venturing into launching your own pet food production line, there are crucial considerations to bear in mind. This guide will detail the essential five tips for initiating a pet food production line. From initial planning to final execution, continue reading to grasp the fundamentals required to kick-start this endeavor.

Understanding a Pet Food Production Line:

Starting a pet food production line presents a lucrative opportunity to generate income while contributing to the well-being of beloved pets. Here are key pointers to commence:

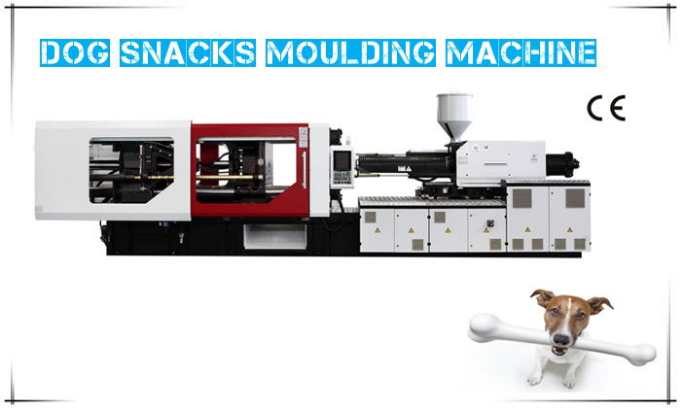

1. Equipment Selection: Begin by carefully selecting the appropriate equipment. A high-volume pet food production machine, sufficient storage capacity for finished products, and dependable machinery are essential prerequisites.

2. Establish Organization: Subsequently, establishing a well-structured organizational framework is crucial. Develop a flowchart or diagram delineating the production process, clarifying logistics, and assigning responsibilities. This step facilitates streamlined operations and ensures stringent quality control measures.

3. Staff Training: Lastly, invest in comprehensive training for your staff to proficiently operate the production line. Ensure they grasp each production step intricately, discern when to adhere strictly to instructions, and when to exercise initiative.

These steps serve as a foundational guide for setting up and managing a successful pet food production line.

Types of Pet Food Production Lines

Choosing the ideal pet food production line among the various available options can be challenging. Common categories encompass dry feed production lines, wet feed production lines, extrusion production lines, and tablet production lines.

Dry feed production lines specialize in crafting kibble or biscuits, while wet feed production lines focus on creating soups, gravies, and other liquid-based products. Extrusion production lines are dedicated to forming pellets or kibble from a blend of grains and ingredients, while tablet production lines manufacture small tablets using proteins, minerals, and other components.

Each type of pet food production line carries distinct advantages and drawbacks. Dry feed production lines typically boast higher speeds than wet feed production lines, albeit potentially limiting flavor and texture variety. Wet feed production lines tend to be cost-effective but might necessitate more space and machinery. Extrusion production lines prioritize speed but could require a higher level of expertise for operation compared to tablet production lines.

The Different Parts of a Pet Food Production Line

A pet food production line comprises several integral components, each playing a vital role in the manufacturing process. Here's an overview of the key elements:

1. Feed Mill: This section processes animal feed into raw materials for pet food products. Tasks include grain crushing and extraction of oils and proteins essential for producing ingredients such as kibble and biscuits.

2. Batch Plant: Responsible for producing large quantities of pet food items simultaneously, the batch plant transforms dry goods like cereals and pellets into formulations ranging from moist kibble to canned dog or cat food.

3. Canning Line: This machine seals cans of pet food using hot and cold waxes to prevent spoilage. Additionally, it prints crucial identification details on can lids, including product name, lot number, expiration date, weight, and nutritional values.

4. Palletizer: These machines handle the loading of product batches onto pallets (large wooden boards). These pallets are then transported to distribution centers or directly to retailers and consumers' homes for further processing or consumption.

![0S4U]EU@J~U``I9[)]D02U2.png 0S4U]EU@J~U``I9[)]D02U2.png](https://www.dragonextruder.com/data/upload/ueditor/20231219/6581380905bad.png)

How to Set up a Pet Food Production Line

Embarking on a pet food production line offers a rewarding opportunity to both generate revenue and cater to our beloved pets. Here are steps to kick-start this venture:

1. Equipment Selection: Begin by selecting appropriate equipment. Ensure ample space to accommodate all machines and adequate storage capacity for the final products.

2. Ingredient Selection: Choose the ingredients crucial for your chosen pet food types and determine the necessary quantities required for production.

3. Production Line Setup: Install and interconnect the machines constituting the production line. Simultaneously, conduct comprehensive training sessions for your staff, enabling them to proficiently operate and manage the machinery.

These steps form a foundational framework for initiating and successfully operating a pet food production line.

Advantages of Owning a Pet Food Production Line:

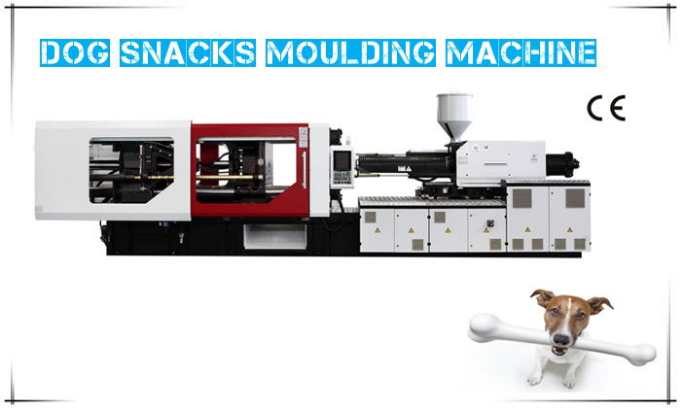

Owning a pet food production line offers numerous advantages, encompassing heightened efficiency, reduced operational expenses, and the capability to yield superior-quality pet food at a more competitive price point.

Primarily, owning a pet food production line bolsters efficiency. Through large-scale production, significant time and monetary savings are achievable. Moreover, the utilization of cutting-edge technology in the manufacturing process ensures the creation of top-tier pet food, surpassing individual production capabilities.

Furthermore, lower operational costs stand out as a significant benefit. Expenses such as rent, salaries, advertising, and marketing are eliminated. Additionally, concerns related to maintenance and inventory shortages are expertly managed by professionals operating the pet food production line.

Ultimately, the most prominent advantage is the capacity to craft high-quality pet food at a reduced cost. This is facilitated by the implementation of advanced equipment and methodologies, resulting in enhanced efficiency and stringent quality control measures.

![0S4U]EU@J~U``I9[)]D02U2.png 0S4U]EU@J~U``I9[)]D02U2.png](https://www.dragonextruder.com/data/upload/ueditor/20231219/6581380905bad.png)