Food extrusion requires a bioreactor system , which pushes several mixed components through a narrow shaped opening called a die, to form various products called extrudates.

Hot extrusion, cold extrusion, co-extrusion and steam-induced extrusion are the main categories used in food extrusion processes worldwide. Food products passing through an extruder system are typically converted to a molten state and encapsulated within the barrel in a high temperature, high shear and high pressure environment generated by a single or multiple set of screws. When the mixture being extruded into the system encounters a sudden drop in temperature and pressure, it expands and forms a cooked product.

What makes food extrusion technology so special?

Extrusion technology has rapidly spread to many areas of food processing and manufacturing. Roll, screw and piston extruders are the most common types of extruders used in the food industry. Initially, these extruders were used to process sausages and meats, especially piston extruders; however, they were quickly replaced by screw extruders to simplify the process.

Screw extruders typically use multiple, single or twin screws that rotate inside a metal cabinet called a barrel. These screws are responsible for guiding the components forward through the orifices (dies), giving them different sizes and shapes.

When single-screw extruders began to be used in pasta production, this innovation revolutionized the food industry with superior functionality and speed. As early as the 1980s, it allowed food industry professionals to discover the potential of extruder systems for diversifying food extrusion options, leading to the expansion and invention of a wide variety of food products.

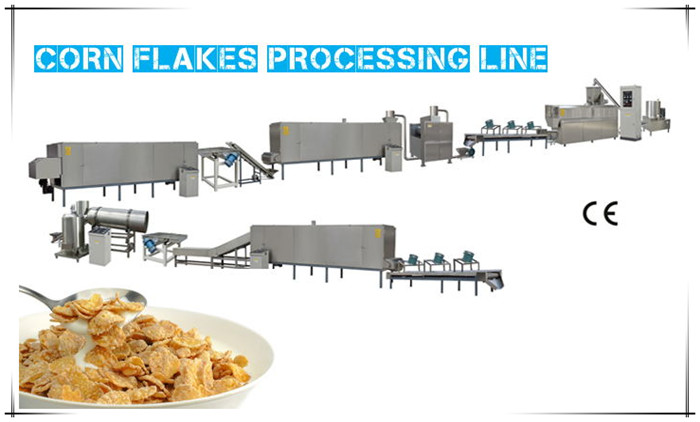

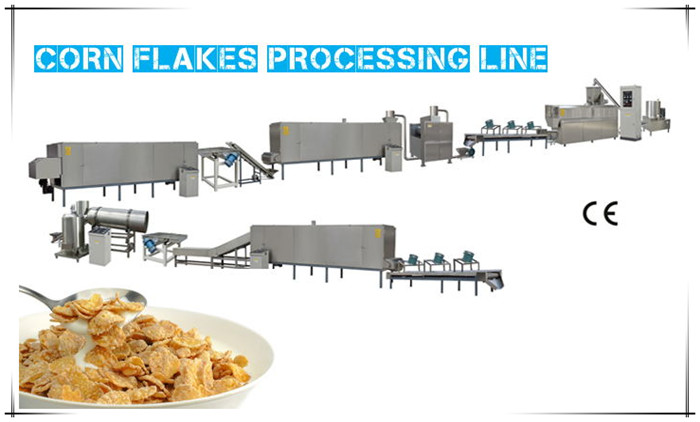

Today, extruders offer an incredible amount of versatility and variability with significant efficiency and low production costs compared to most other food processing methods. They are widely used to produce many types of ready-to-eat pasta, cereals, chewing gum, snacks, aquafeed, pellet products, baby and pet food, and hundreds of other food products.

How has the extrusion process revolutionized the food processing industry?

Data shows that the global puffed food market has grown at a rate of more than 4% over the past few years. Many expect this growth to continue as emerging markets continue to grow due to increased urbanization and the busy lifestyles most people around the world lead.

From fibrillated proteins such as plant-based organised "meats" to third-generation "semifinished" products that can later be fried, burst or puffed, food extrusion technology allows consumers to immerse themselves in new culinary experiences. The process also helps pet parents ensure that they are feeding their pets nutritious but affordable extruded foods.

As people choose to make more sustainable choices, food extrusion offers convenient and healthy food options that are produced ethically to ensure quality. Because extrusion seems to me to be more economical, versatile and efficient, it not only plays a key role in the current food extrusion industry, but it appears to have a bright future.

From extruder operation and maintenance to extruder operator training and specialized machine design, we offer a complete package to help you streamline your food processing or waste processing plant.

If you want to invest in advanced extruder processing technology, contact us.