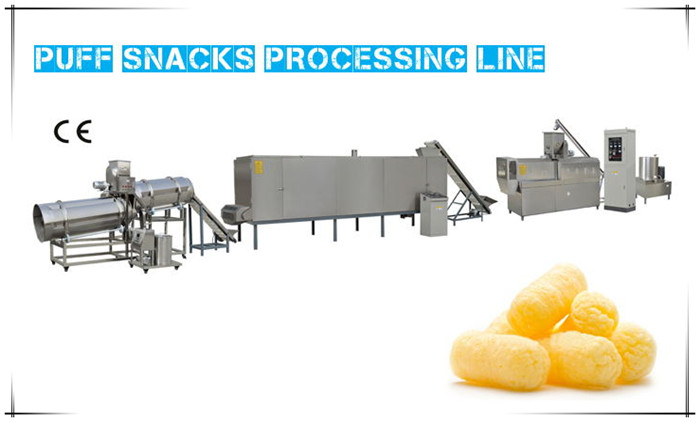

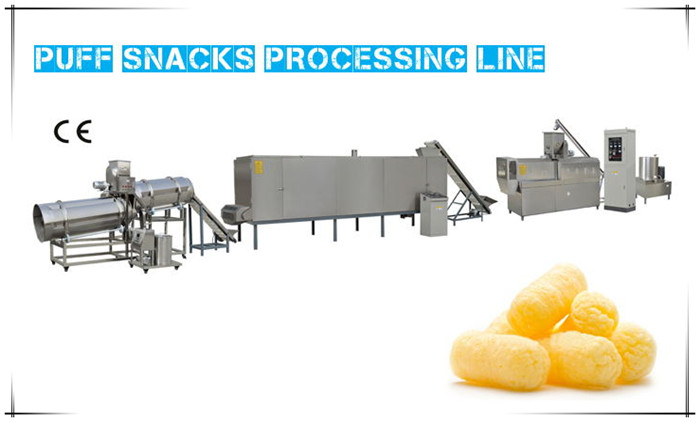

The food puffing machine is small in size, low in price, low in noise, light in weight, compact in structure and simple in operation. Here are some suggestions from Food Extrusion Equipment Manufacturer for the maintenance of Puff Snacks Processing Line. I hope to help you.

1. The expanded raw materials should be cleaned to prevent foreign objects such as metal from entering the machine and damaging the parts;

2. The wearing parts such as screw and screw sleeve are strictly prohibited from being hardened with hard objects during the disassembly and assembly process. It is strictly forbidden to place heavy objects or stand on the expansion chamber;

Puff Snacks Extruder

3. When using Puff Snacks Processing Line or replacing bulk material for long-term shutdown, the material in the expansion chamber should be cleaned to avoid agglomeration, mildew or cross-contamination between materials;

4. The tank bearing should be filled with grease in time. After running for 500 hours, replace the grease once. (The grease should be added in an appropriate amount before the new machine is operated. After 200 hours of operation, the oil should be changed.)

5. Puff Snacks Extruder wears relatively close to the discharge port, and the wearing parts near the inlet end wear less. Therefore, when replacing consumable parts, it should be replaced from the discharge end. Replace multiple parts at once.