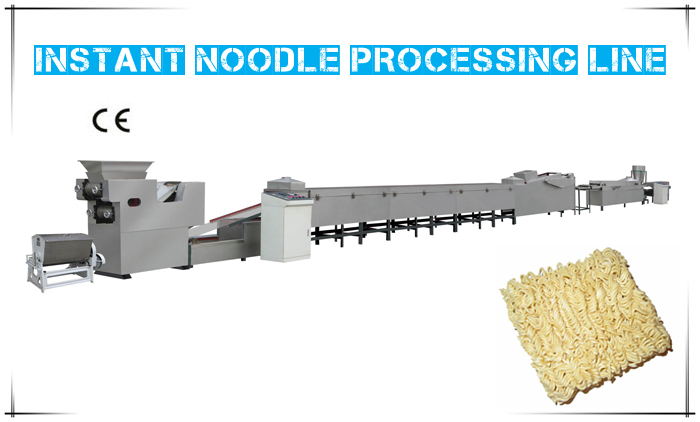

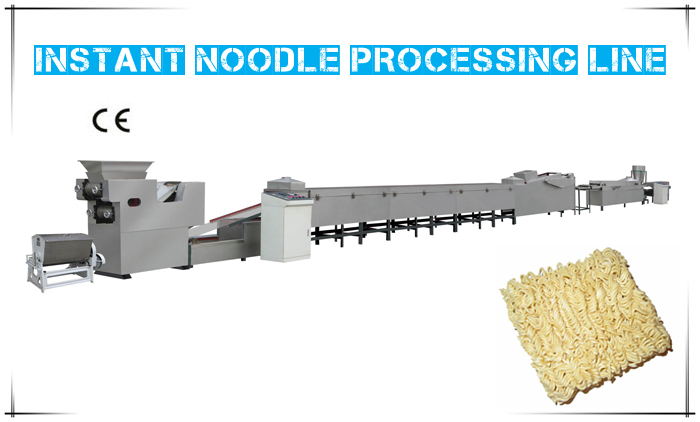

Instant noodles are noodle-based foods that can be cooked and consumed in a short period of time. It is very popular because of its convenience and speed. Because of its huge demand, the instant noodle processing line is very important in instant noodle making. The instant noodle processing line has a high degree of automation, easy operation, low energy consumption, small footprint, and ensures that all processes from feeding powder to finished products are completed at one time.

What is the Main Equipment Included in the Instant Noodle Processing Line?

Mixing Machine

There are many kinds of noodle mixing machines and the most commonly used one is horizontal noodle mixing machine. Its structure is simple, manufacturing costs are generally low, easy to unload and clean, but occupies a large area. Horizontal and the production capacity of the machine that is a large range of powder capacity. It is currently the most common application of various sizes of food factories at home and abroad to adjust the flour equipment.

Waking and Maturing Machine

Waking and maturing machine, maturing is one of the important links to further improve the processing performance of dough and improve product quality. Because in the process of mixing dough, the dough is subjected to the blow of mixing teeth of the mixing machine and the mutual collision between the dough and the shell, so that the initial formation of gluten mass of the dough is squeezed and stretched to produce stress, this dough is processed into noodles, and the noodles will have an unstable internal structure and be easily deformed, and the maturing process can eliminate this stress.

Composite Calender

Compound calender is the dough after maturing and dough through multiple rolling to form the required dough sheet, compound calendering is also known as pressing, rolling or rolling. Compound calendering will further promote the fineness and mutual adhesion of the gluten network during the pressing process, and finally evenly arrange in the dough sheet, so that the dough sheet has certain toughness and strength to ensure product quality.

Noodle Steaming Machine

The steamer is the most important part of the instant noodle manufacturing process. The basic principle of manufacturing instant noodles is to paste the formed raw noodles and then dehydrate them quickly to get the product. The steaming process is an important part of instant noodle production, which not only affects the degree of battering and rehydration, but also has a great impact on the oil content of instant noodles.

Quantitative Cutting Equipment

The quantitative cutting process is complex and is a unique multifunctional process in the instant noodle production line. It uses the folding plate mounted on the crank linkage mechanism to make reciprocating movement while cutting, so that the folding plate is inserted in the middle of the cut noodle belt and inserted between the folding guide roller and the dividing conveyor belt to fold the steamed and cut noodle belt in rows and output it to the next drying process. According to the customer's needs, it can make square or round pastry of different specifications.

Deep-frying and Dewatering Machine

Deep-frying and dewatering is to put the quantitatively cut noodles into the chain box of automatic fryer, and make them pass through the high temperature oil tank continuously. The noodles are surrounded by high temperature oil, and the temperature itself rises rapidly, and the moisture contained in them vaporizes rapidly. The purpose of dehydration is to reduce the moisture to facilitate storage, while improving the quality of its products.

Hot Air Dryer

Hot air drying is the drying method for producing non-fried instant noodles. As the instant noodles have been steamed at a high temperature of 95~100℃ or more, most of the starch contained therein has been pasted, the gluten made up of protein has been denatured and solidified, and the tissue structure has been basically fixed, which is different from the internal structure of unsteamed noodles and can be dried at a higher temperature and lower temperature in a shorter period of time.

Cooling Device

The fried instant noodles have a higher temperature after deep-frying, and when transported to the cooling machine, the temperature is generally still around 80~100℃. Hot air drying instant noodles from the dryer when the noodles arrive at the cooling machine, its temperature is still about 50 ~ 60 ℃, these noodles if not cooled directly packaging will lead to noodles and soup material is not resistant to storage, if the cooling does not reach the predetermined standard, will also cause moisture absorption and mold inside the package, and therefore cooling of the product is necessary.

Jinan Qunlong Machinery Co., Ltd. is majored in manufacturers of food extruder machine and pet food machine. If you want to know more information about them, please contact us. We will provide professional answers.