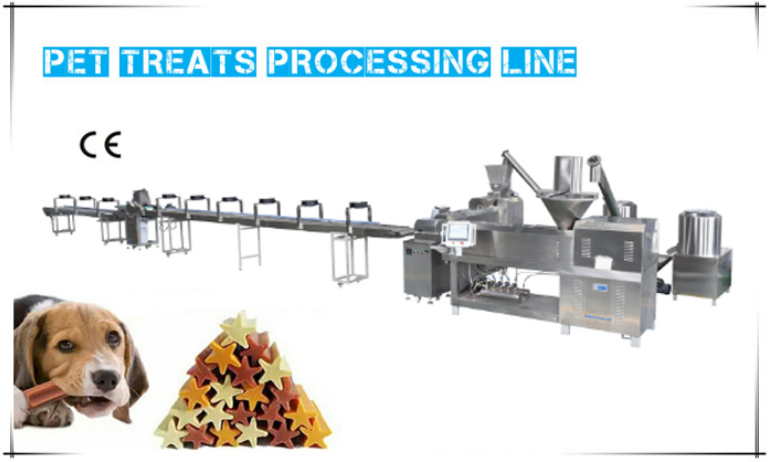

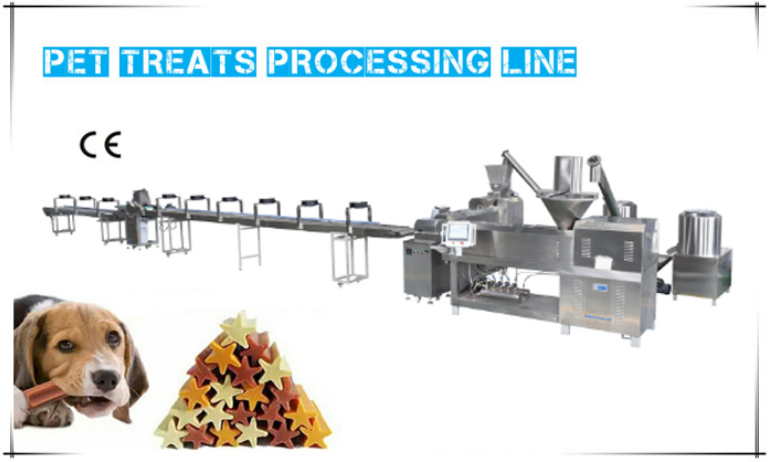

The pet food industry is booming, and with it, the demand for high-quality dog food is skyrocketing. For businesses looking to enter or expand in this market, choosing the right dog food production line is crucial. This guide will help you navigate the various factors to consider when selecting a suitable production line for your needs.

Understanding Dog Food Production Lines

Dog food production lines are systems that encompass various machines and processes to manufacture dog food. These lines can produce dry kibble, wet food, semi-moist food, and more, tailored to different dietary needs and preferences.

Key Factors to Consider

1. Production Capacity

One of the first considerations is the production capacity of the line. You need to assess your current and projected output requirements:

- Small-scale production: Ideal for startups or niche markets.

- Medium to large-scale production: Suitable for established businesses with higher demand.

2. Types of Dog Food

Different production lines are designed for specific types of dog food:

- Dry kibble: Requires extrusion and drying processes.

- Wet food: Involves cooking, canning, or packaging in pouches.

- Semi-moist food: Combines elements of both dry and wet food production.

3. Flexibility and Scalability

Consider how flexible and scalable the production line is:

- Flexibility: Ability to produce various dog food products with minimal changes.

- Scalability: Capability to expand production capacity as your business grows.

4. Quality and Safety Standards

Ensure that the production line meets high-quality and safety standards:

- Hygiene: Equipment should be easy to clean and maintain to prevent contamination.

- Regulatory compliance: Machines should comply with local and international food safety regulations.

5. Energy Efficiency

Energy-efficient production lines can significantly reduce operational costs. Look for equipment that optimizes energy use without compromising performance.

6. Automation Level

Automation can streamline production and reduce labor costs:

- Manual: Suitable for low-budget operations with limited output.

- Semi-automatic: Balances cost and efficiency, ideal for moderate production.

- Fully automatic: Maximizes efficiency and output for large-scale production.

Essential Components of a Dog Food Production Line

1. Raw Material Handling System

Efficient handling and storage of raw materials are critical:

- Conveyors: Transport raw ingredients to different processing stages.

- Storage bins: Keep ingredients organized and accessible.

2. Mixing and Blending Equipment

Ensures that ingredients are thoroughly mixed for consistent quality:

- Mixers: Combine dry and wet ingredients.

- Blenders: Ensure uniform distribution of components.

3. Extrusion and Cooking Systems

Critical for producing dry kibble and some wet foods:

- Extruders: Shape and cook the dough under high pressure and temperature.

- Cookers: Cook ingredients to the desired level.

4. Drying and Cooling Machines

These machines remove moisture and prepare the food for packaging:

- Dryers: Reduce moisture content to extend shelf life.

- Coolers: Lower the temperature of the product before packaging.

5. Packaging Solutions

Proper packaging ensures product freshness and convenience:

- Fillers and sealers: Package the food in bags, cans, or pouches.

- Labelers: Apply labels for product identification and branding.

6. Quality Control Systems

Automated quality control systems can detect defects and ensure consistency:

- Metal detectors: Check for contamination.

- Weight checkers: Ensure accurate portion sizes.

Maintenance and Support

1. Routine Maintenance

Regular maintenance is crucial to prevent breakdowns and ensure longevity:

- Scheduled servicing: Follow the manufacturer's maintenance schedule.

- Replacement parts: Keep spare parts on hand for quick repairs.

2. Technical Support

Reliable technical support can minimize downtime and maintain efficiency:

- Supplier support: Choose a supplier that offers robust after-sales service.

- Training: Ensure staff are trained to operate and maintain the equipment.

Cost Considerations

1. Initial Investment

Assess your budget and consider financing options:

- Upfront cost: Evaluate the total cost of purchasing and installing the line.

- Financing: Explore leasing or financing options to manage expenses.

2. Operating Costs

Factor in the ongoing costs of running the production line:

- Energy consumption: Choose energy-efficient models to reduce utility bills.

- Maintenance: Budget for routine maintenance and repairs.

Conclusion

Selecting the right pet food machine involves evaluating your production needs, product types, and budget. By considering factors like capacity, flexibility, quality standards, and cost, you can find a production line that meets your business goals.

If you need assistance in choosing the perfect dog food production line or are looking for a reliable supplier, contact us today. We offer a wide range of production solutions tailored to your needs and provide comprehensive support to ensure your success.