Food production and processing is an important part of the development of the food industry. People take food as the sky, and the food processing industry began to appear very early, and it has been passed down by hand. With the continuous advancement of industrialization, China's food industry has achieved rapid growth and the industrial structure has been continuously strengthened and optimized. And driven by downstream demand, China's food processing equipment manufacturing industry has also achieved rapid development.

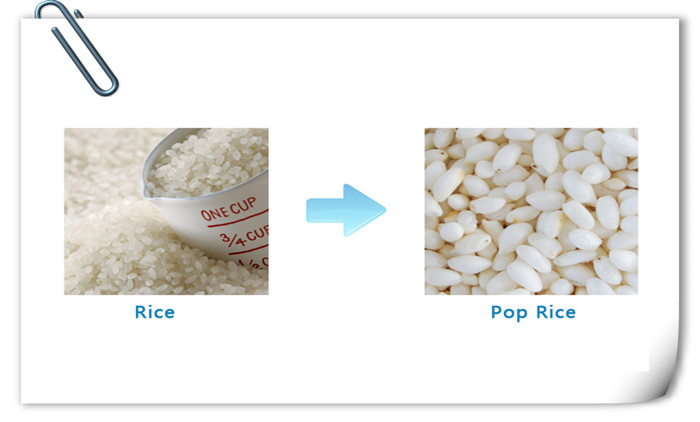

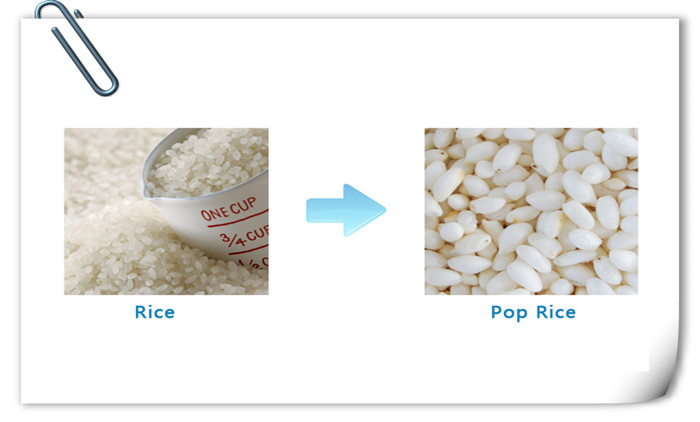

Pop-rice Puffing Machine

The food processing industry and the food machinery manufacturing industry

complement each other. With the continuous improvement of the national economy,

the demand of the domestic food industry continues to escalate, the scale of the

food machinery industry is also expanding rapidly, and the Pop-rice

Puffing Machine is developing rapidly.

For the food industry, deep processing through technical means is one of the

important ways for enterprises to increase food added value.

Therefore, for food production enterprises, it is necessary to use automated

food processing equipment to increase the degree of deep processing of food, so

as to further increase the value of food. In addition, compared with manual

production, automated food processing equipment can reduce the degree of manual

participation to a certain extent, thereby reducing the food safety risks

brought by labor and improving food safety precautions.

Naturally, food machinery and equipment manufacturers cannot stop the pace of

innovative research and development, break through the current situation of

domestically manufactured food machinery that is dominated by low and medium

grades, and use the development of core technologies to improve the technical

level of equipment, thereby promoting the equipment to advanced . Especially

China's food processing is more diverse, so it has higher requirements on the

performance, technology, and scope of application of food machinery.

What is the principle of corn extruder? The following Food Extruder

Machine Supplier will introduce the principle of corn extruder. Let us take a look and hope it will be helpful to everyone.

By using the extruder's non-equidistant non-standard spiral system to push and push, the gas in the material is discharged and quickly filled with the material. The material is affected by the sheer force to return, which increases the pressure in the bore. The friction between the mediator and the machine chamber causes the materials to be fully mixed, squeezed, heated, glued, and gelatinized to produce tissue changes, and the original structure is destroyed. At the same time, the mechanical energy is converted into thermal energy by the friction of the materials in the chamber, so the material becomes a gel state with flowing properties. When the material is squeezed to the

outlet, the pressure changes from high pressure to normal pressure instantly,

and from high temperature to normal temperature instantly, causing the water to

quickly evaporate from the tissue structure, causing countless microscopic

formation inside. The whole structure is passed through a cutting device and is cut and cooled to expand.

Our company also has Protein Bar Forming Machine on sale,

welcome to consult.