As a Food Extruder Machine Supplier, share it with you.

The maintenance of the fryer is very important to the user. If you don’t know

how to maintain it, various problems will occur during the use of the machine in

just a few years. It is either the replacement of many mechanical parts or

various mechanical failures. It brings a lot of inconvenience to the production

of many businesses.

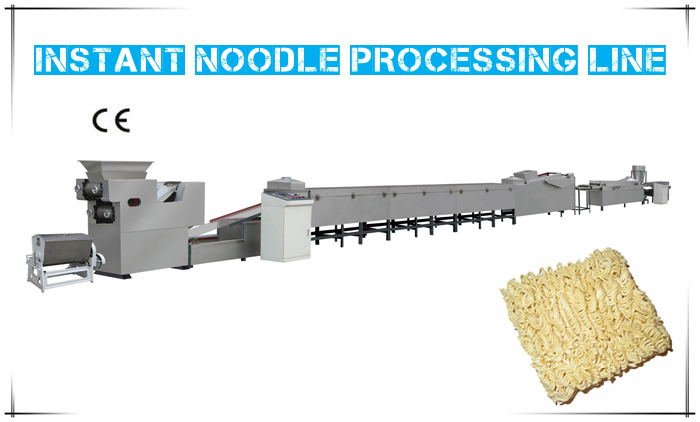

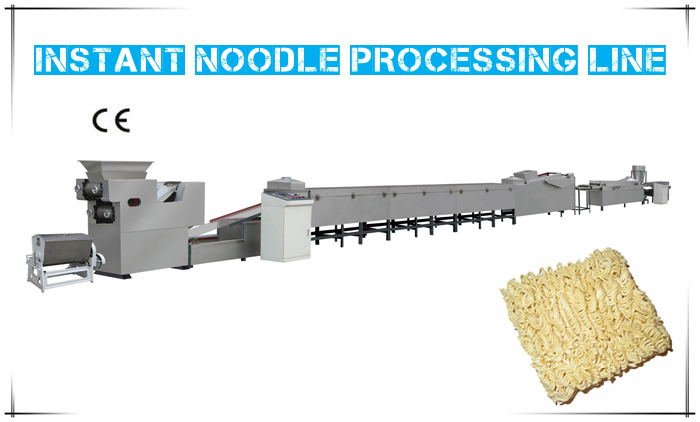

Instant Noodle Processing Line

Below we introduce to you the seven maintenance rules of the fryer:

1. Turn off the power before the equipment is in production.

2. Check whether other parts of the deep-fryer bearing are loose or not

working properly!

3. Connect the power supply and start clockwise (usually it takes about 40-60

seconds from static state to normal operation) to proceed without abnormal

conditions.

4. Generally, each frying equipment must run empty for about 2 hours after

it reaches the buyer.

5. Fryer materials should be placed as evenly as possible. The maximum

capacity shall not exceed the rated capacity of the frame.

6. The fryer must be operated by a dedicated person. So as not to shorten the

service life of food machinery.

Seven. If the food machinery is over-speeding, the machinery should be

stopped immediately if there is an abnormal condition of the machinery or the

operating sound is not right.

Note: Therefore, do not touch the drum machine with your body. The

high-temperature vacuum fryer runs at a constant speed when working. In order to

avoid accidents: turn the mechanical parts and refuel every six months. At the

same time, check the lubrication of the bearing to ensure the normal operation

of the centrifuge.

Our company also has Instant Noodle Processing Line on sale, welcome to

contact us.