Cereal bars have become a popular snack choice for people looking for convenient and nutritious options on the go. With their rising demand, investing in a cereal bar production line can be a lucrative venture. However, before diving into such an investment, it's essential to understand several key aspects of cereal bar production lines. Here are five things you should know before making a decision:

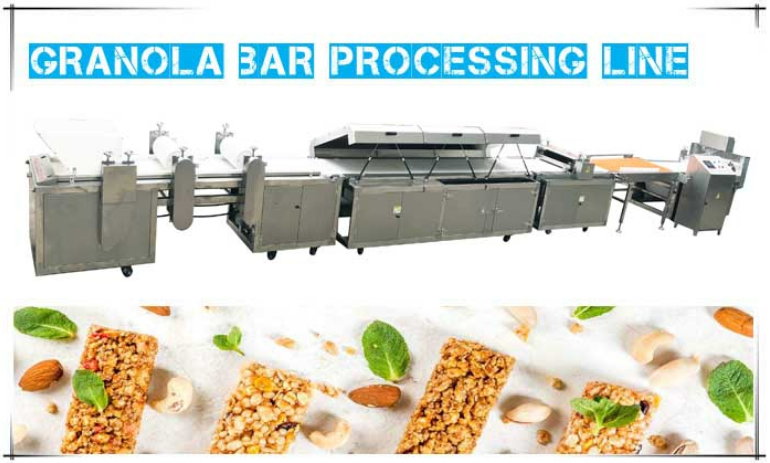

Understanding the Cereal Bar Production Line

A cereal bar production line is a complete equipment system designed to produce cereal bars and other snack foods efficiently. It consists of various machines that work together to mix, shape, cook, and package the final product. These lines are capable of handling a wide range of ingredients, including grains, nuts, chocolate, and fruits, allowing for the production of diverse cereal bar varieties.

Types of Cereal Bars Produced

Cereal bars come in various flavors and formulations, making them versatile snacks for consumers. They can be made from grains such as cornflakes or wheat flakes, and can also incorporate ingredients like nuts, chocolate chips, and dried fruits. Understanding the types of cereal bars you intend to produce is crucial in selecting the appropriate production line and equipment to meet your manufacturing needs.

Different Types of Production Lines

Cereal bar production lines vary in complexity and capabilities, ranging from basic setups to fully automated systems. Basic lines typically include essential equipment such as mixers, extruders, ovens, and cutting machines. More advanced lines may incorporate additional features like cooling conveyors, coating machines, and packaging systems. Assessing your production requirements and budget will help determine the most suitable type of production line for your business.

Continuous vs. Batch Production

Cereal bar forming machine can operate in either continuous or batch mode. Continuous production lines feature a conveyor belt system that moves the product through each stage of production seamlessly, allowing for high-speed and continuous output. On the other hand, batch production lines process one batch of product at a time, filling the conveyor belt before advancing to the next stage. Understanding the pros and cons of each production method is essential in optimizing efficiency and output.

Maintenance and Cleaning Requirements

Maintaining optimal performance and hygiene standards is vital in cereal bar production. The materials used in the production line, such as stainless steel or plastic, will dictate the frequency and method of cleaning. Regular maintenance of equipment components like mixers, extruders, and cutting blades is essential to prevent downtime and ensure product quality. Considering the maintenance requirements of a cereal bar production line is crucial in planning for ongoing operational costs and resource allocation.

Investing in a cereal bar production line can be a significant undertaking, but with careful consideration of these key factors, you can make an informed decision that aligns with your business goals and objectives.

For inquiries about cereal bar production line suppliers or further information on cereal bar production, please don't hesitate to contact us.